In 1968, Rob Shirley embarked on a mission driven by a singular vision—to build the best ski boat in the industry. While he came from a competitive waterskiing background, Rob's passion for the sport extended beyond participation. Unsatisfied with the performance of the ski boats on the market at the time, Rob was determined to redefine the standard, harnessing his insights into what would make a boat truly exceptional—superior turning, impeccable tracking, and the ability to produce unrivaled wakes.

After countless hours, Rob brought his vision to life, debuting the 18-foot groundbreaking ski boat bearing the name “MasterCraft” and forever altering the course of the towboat industry. This very first MasterCraft—and each one after it—have been meticulously built by hand. And still to this day, every MasterCraft built upholds this legacy, handcrafted by dedicated engineers and passionate boaters who carry the torch that Rob lit all those years ago.

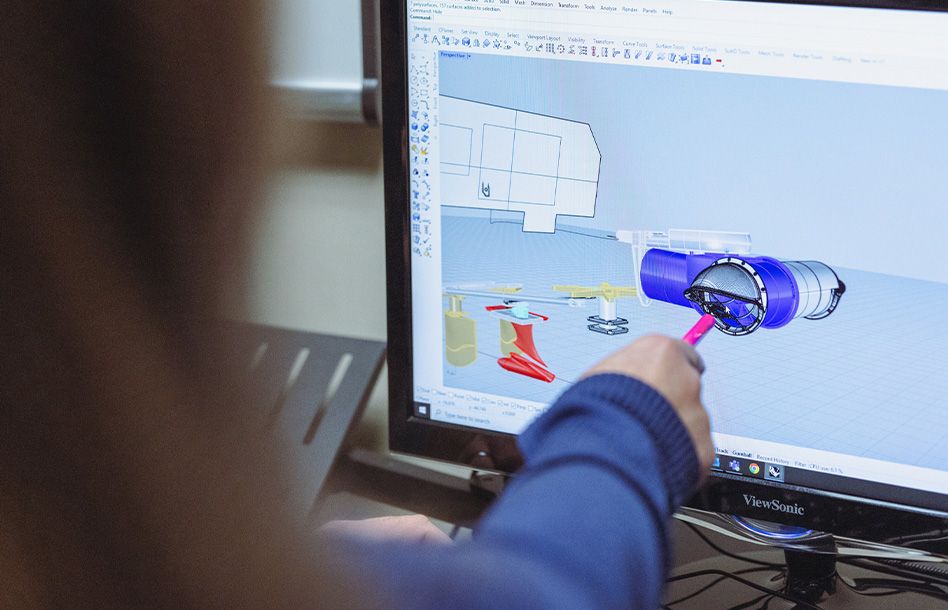

Erica’s career in engineering started over twenty-five years ago. Prior to MasterCraft, she gained experience in design, quality, and manufacturing roles, which eventually grew into leadership positions where she led cross-functional and global teams. Erica has taken that diverse experience and applied it to her role at MasterCraft, where she has been the director of engineering for four years, leading both the current product team and the new product development team.

She and her teams are constantly looking at ways to improve current product and enhance the new generation of boats, while strategizing and developing new features and models to make your on-water days the very best. As director of engineering, Erica has her hands in every segment of her team’s day-to-day work, from coming up with new ideas and prototyping them to then seeing these new innovations come to life.

Zach’s career with MasterCraft began over eight years ago and has seen him through many stages of the boat building process. Before his role in the engineering department, Zach worked in the quality department, then was a lake tester, an assembly inspector, a final finish inspector, and even more over the years. His vast experience and ability to do it all has made Zach a valuable member of the MasterCraft family. Currently, his role includes assisting engineers with any new or ongoing projects, performing maintenance on engineering fleet boats, and overseeing all canvas fittings—including the bimini, bow and aft sunshades, mooring cover, and shipping cover, and all relations with those respective vendors.

Zach also plays an instrumental part in providing support for sales, marketing, or investor events. Through his passion and personal experience as a wakeboarder and boater, Zach is able to put himself in MasterCraft customers’ shoes, see the bigger picture, and help create a product that he is extremely proud of and knows others will love.

Silvestre has been with MasterCraft for over seventeen years, starting in lamination his first year and then working as a gel coater for the remaining sixteen. Silvestre prides himself on his technique and precision when spraying the molds with gel coat, noting that it takes time and a lot of dedication to ensure it’s done right so the final product is perfect for you. The work that Silvestre does is extremely important because the gel coat is the first thing you see when you look at a MasterCraft.

Silvestre says, “It makes me proud when I see a MasterCraft, and I remember the colors, and I say to myself, ‘There’s a good chance I sprayed that boat.’ And it makes me feel good.”

Rick has been with MasterCraft for over seven years, with the most recent four years working as a hull-finisher. His role is a vital step in the boat building process, strengthening the hull and further waterproofing it to ensure its durability for you and your family. Rick is proud of the attention to detail that goes into his work and having a hand in delivering the quality that MasterCraft is known for. As one of three Dennis generations to build these boats, Rick and his family's legacy runs strong through MasterCraft.

Leann has worked at MasterCraft for over twenty years and truly embodies the meaning behind being part of the MasterCraft Family. One of the reasons she enjoys coming to work is “because I [Leann] have friends and family here at MasterCraft. It has been a life experience for me and my children.”

As an upholstery sewer, Leann is responsible for going through boat orders, finding the materials she needs from the cutting table, and then assembling them depending on which area of the boat they are needed. After Leann has assembled the upholstery, she delivers it to the assembly area for that specific part, where it is attached to the fiberglass and then eventually to the body of the boat.

Donna has worked at MasterCraft for over fifteen years and considers every day at MasterCraft a great day. She recently was promoted to a supervisor of the small parts department, where she and her team meticulously craft speaker inserts, bow lids, dashes, shifter panels, and more. Donna ensures that her department maintains the highest-quality standards so that each small part that is placed in your MasterCraft is perfected.

Regarding her team, Donna says, “It’s an awesome crew to work with. Everybody is a team player and works together.” And together, they all take pride in what they do and the contributions they make. “It is a gorgeous product once it’s completed and out the other door.”

Jacob started at MasterCraft over ten years ago in assembly, but he’s spent the last four years on the water as a lake tester. His role is an important stage in the boat building process because it’s the final quality check before the boat is shipped to the dealers and then into your hands. Jacob and the team of lake testers take each boat out on the water and go through a series of checks: ballast, the various tabs for surfing, skiing, wakeboarding, and driving modes, turning and wide-open throttle, electrical and speakers, docking and underwater lights, all the functionalities of the dash, and more. Through rain or shine, Jacob has tested over 2,000 MasterCraft boats.

Shelly started working for MasterCraft over twenty-eight years ago as a way to support her husband and their newborn baby. That job quickly turned into a career—one where she is proud to be a part of that first impression a customer has when they finally lay eyes on their new MasterCraft boat. As a rigger, Shelly is responsible for meticulously placing the MasterCraft decals, warning labels, and transom scratch protection, and then ensuring the boats are shined up and ready to go.

Shelly works together with several other departments to ensure every boat that leaves the factory is perfected for the customer. When asked what HandCrafted means to her, Shelly says, “Each one of us has our hands on the boat and are so proud of what we do.”

Josh has been with MasterCraft for more than seven years. He began in the welding line and has worked his way up to Team Leader of the Trailer Shop. He is responsible for completing work orders, setting the schedule for the shop and trailers, and managing the trailer shop team. He accomplishes this by hosting morning meetings that include reviewing the previous day’s work while boosting camaraderie within the shop to ensure everyone works as a team.

Josh says, “I have a lot of great days at MasterCraft… I truly do.” Josh notes that he is especially grateful for his team, saying, “We have good people, and it’s very family-oriented. My team makes it easy to lead, and being their team leader makes me proud.”